When it comes to high-performance materials, POM sheets/POM Rods stand out for their durability and versatility. Made from polyoxymethylene, they offer excellent strength and wear resistance, making them ideal for various applications. Whether you’re in automotive or electronics, understanding the properties and grades of POM sheets/POM Rods can help you make informed choices. But what exactly sets them apart from other materials, and how can you choose the right one for your needs?

What exactly is a POM sheet/POM Rod? A POM sheet/POM Rod, made from polyoxymethylene material, is a versatile acetal plastic known for its strength and durability.

You’ll find that this pom plastic is often available in two types: POM-C and POM-H. The POM-C, or copolymer, offers enhanced chemical resistance, making it ideal for various applications.

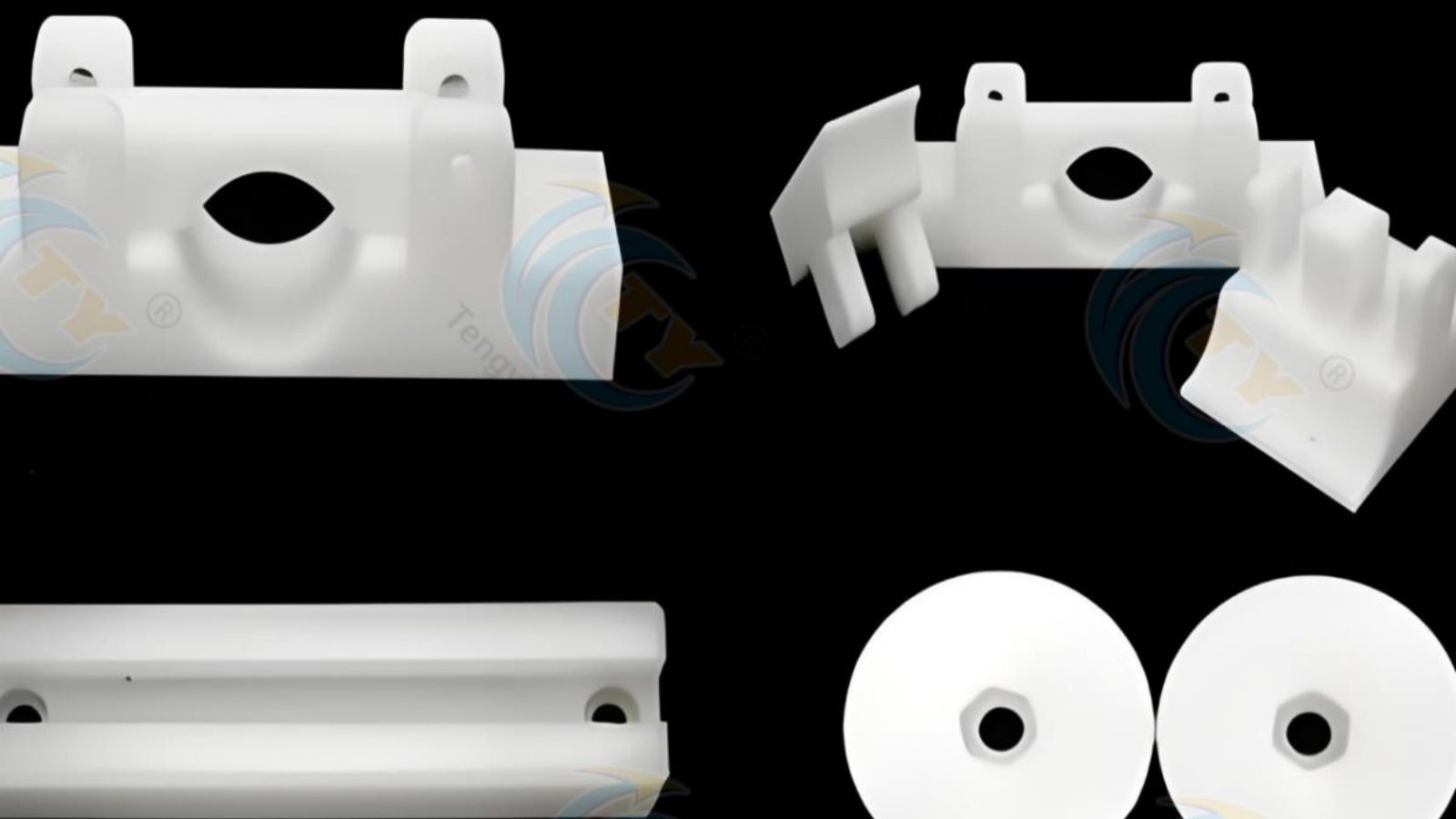

This acetal pom is lightweight yet sturdy, making it perfect for precision parts like gears and bearings.

When you use POM plastic material, you're choosing a solution that provides excellent dimensional stability and low moisture absorption.

Whether in automotive parts or consumer electronics, POM sheets/POM Rods offer a reliable choice for those who value quality and performance in their projects.

When considering POM sheets/POM Rods, you'll appreciate their high mechanical strength and rigidity, making them ideal for demanding applications.

Their excellent wear resistance and low friction properties enhance longevity, while good dimensional stability guarantees precision in various conditions.

Additionally, POM sheets/POM Rods resist chemicals and moisture, maintaining performance even in challenging environments.

POM sheets/POM Rods boast remarkable mechanical strength and rigidity, making them ideal for demanding applications. When you choose POM, you’re opting for a material that can withstand heavy loads and resist deformation, ensuring your projects are built to last.

Whether you’re crafting precision components for automotive parts or creating durable fixtures in the medical field, POM's high tensile strength assures you of reliability. You'll appreciate how well it maintains its shape under stress, fostering a sense of confidence in your creations.

By integrating POM sheets/POM Rods into your work, you’re joining a community that values durability and performance. Elevate your projects with POM, and feel the difference in quality and resilience.

You belong in this innovative world where strength meets functionality.

Building on POM's impressive mechanical strength, its excellent wear resistance and low friction properties further enhance its appeal for a variety of applications. These features make POM sheets/POM Rods ideal for components that experience constant motion, such as gears and bearings. By minimizing friction and wear, POM not only extends the lifespan of your parts but also improves overall efficiency.

Embrace POM for your projects and experience its exceptional performance!

How does POM maintain its shape under varying conditions? POM sheets/POM Rods exhibit excellent dimensional stability, ensuring they hold their form even when exposed to temperature fluctuations and humidity changes. This stability is essential for precision parts, like gears and bearings, where tight tolerances matter.

When you choose POM, you’re opting for a material that won’t warp or shrink, creating a reliable fit in your applications. Its low thermal expansion means you can count on consistent performance, fostering a sense of trust in the materials you use.

Whether you're in manufacturing or design, POM's stability helps create a cohesive environment where everything works seamlessly together, enhancing both your projects and your sense of community.

Maintaining dimensional stability is only part of what makes POM sheets/POM Rods a reliable choice for various applications. Their exceptional chemical and moisture resistance guarantees they perform well in challenging environments.

You’ll find that POM sheets/POM Rods can withstand exposure to many solvents and oils without degrading, making them a go-to material for industrial use.

While POM sheets/POM Rods offer excellent performance in various applications, their temperature resistance is an essential factor to contemplate. Generally, POM can withstand temperatures ranging from -40°C to 120°C. This range makes it suitable for many environments, but it’s important to note that prolonged exposure to temperatures above 160°C can impact its performance.

For your projects, understanding this thermal limit guarantees you’ll achieve the durability and reliability you need. Additionally, if you're working in extreme conditions, consider the specific requirements of your application.

With POM sheets/POM Rods, you’re choosing a material that balances strength and temperature stability, making it a dependable choice for those who value quality and performance in their work.

When you consider POM sheets/POM Rods, you'll find they're incredibly versatile across various industries.

From automotive parts like gears and fuel systems to precision engineering components, POM sheets/POM Rods play a vital role in enhancing performance and durability.

They also meet food safety standards, making them ideal for food processing equipment and consumer electronics.

As automotive technology evolves, the demand for high-performance materials like POM sheets/POM Rods increases, particularly for critical components such as gears, bushings, and fuel systems.

You’ll find POM’s remarkable qualities make it a go-to choice in automotive applications, providing reliability and efficiency.

Building on the reliability seen in automotive parts like gears and bushings, POM sheets/POM Rods are also highly effective in industrial machinery components such as bearings and pulleys. When you choose POM for these applications, you’re opting for materials that provide excellent wear resistance and low friction, ensuring smooth operations.

Because POM maintains its shape under stress, it’s perfect for components that require precision and durability. You'll find that POM’s resilience translates to longer lifespans for your machinery, reducing downtime and maintenance costs.

How can POM sheets/POM Rods enhance the safety and efficiency of food processing equipment? By utilizing FDA-compliant POM sheets/POM Rods, you ensure that your equipment meets strict safety standards while benefiting from the material's superior properties.

These sheets/rods provide durability and resistance to wear, making them ideal for various applications in food processing.

Using POM sheets/POM Rods in your food processing equipment not only improves safety but also fosters a reliable environment, connecting with others who prioritize quality and compliance in the industry.

What makes POM sheets/POM Rods a go-to choice in consumer electronics and tools? Their impressive strength and low friction properties make them ideal for various applications. You’ll find POM sheets/POM Rods used in everything from gears to keypads, enhancing the durability and performance of your favorite devices. Here's a quick overview of how POM stands out:

Application | Benefits

With POM sheets/POM Rods, you’re not just getting functionality; you’re investing in products designed for longevity and reliability, making your everyday experiences smoother and more enjoyable.

Why is POM such a popular choice in precision engineering? Its remarkable properties make it ideal for producing high-quality components that require exact tolerances and durability.

When you choose POM, you’re tapping into a material that stands out in various applications:

Choosing the right POM sheet/POM Rod for your project can feel overwhelming, but it doesn’t have to be. By understanding your specific needs, you can confidently select the best option.

Selecting the ideal POM sheet/POM Rod may seem daunting, but knowing your requirements will guide you to the perfect choice.

Keep these key factors in mind:

To effectively work with POM sheets/POM Rods, it's crucial to understand their unique properties and how they respond to different machining methods. Start by using sharp tools; this minimizes chip formation and guarantees a clean cut. Keep your feed rates moderate to prevent overheating, which can lead to warping.

When drilling, use a slower speed and don’t forget to apply coolant to maintain temperature control. Always clamp securely to avoid movement during machining. If you're shaping edges, consider a radius to reduce stress concentrations.

Lastly, take advantage of POM's self-lubricating properties; it helps in reducing friction in applications. By following these tips, you'll foster a sense of community with others working with POM, enhancing collaboration and shared success.

When it comes to sourcing POM sheets and POM rods, working with a dependable supplier is key to ensuring consistent quality and long-term success. At Tengyi Plastic, we are committed to providing high-performance polyoxymethylene materials tailored to the needs of engineers, fabricators, and industrial buyers worldwide.

By partnering with Tengyi Plastic, you benefit from:

Choosing Tengyi Plastic means more than buying raw materials—it means building a partnership based on trust, reliability, and shared standards of excellence. As your trusted POM supplier in China, we’re here to help you move forward with confidence.ing in a partnership that supports your goals and enhances your capabilities.

POM sheets/POM Rods maintain stability in extreme temperatures, performing well up to 160°C for short periods. You’ll appreciate their resilience and low thermal expansion, making them ideal for precision applications even in challenging environments.

You’ll find recycling POM sheets/POM Rods challenging due to their thermal properties. While some facilities accept them, reusing POM sheets/POM Rods for crafting or DIY projects can be a creative way to minimize waste and be resourceful.

You’ll find POM sheets/POM Rods in various colors, including natural white, black, and custom shades. This variety allows you to choose what suits your project best, ensuring a perfect match for your design needs.

To guarantee POM sheets/POM Rods last, store them in a cool, dry place, away from direct sunlight. Keep them flat or in a vertical position, avoiding heavy stacking. This way, you’ll maintain their quality and integrity.

Yes, there are specific certifications for POM sheets/POM Rods across various industries, like FDA approval for food applications or ISO standards for quality assurance. You’ll want to check these certifications based on your intended use.

In summary, choosing the right POM sheet/POM Rod is essential for ensuring your project's success. With its impressive properties and versatility, POM is a top choice for various applications. Remember to take into account factors like grade certifications and supplier support when making your selection. By following the expert buying guide and tips for working with POM sheets/POM Rods, you can achieve reliable, long-lasting performance in your projects. Trust a reputable supplier in China to meet your needs and elevate your results.