PEEK Sheet – High-Performance Engineering Plastic

PEEK (Polyether Ether Ketone) sheet is an advanced thermoplastic renowned for its exceptional mechanical strength, thermal stability (up to 260°C), and chemical resistance.

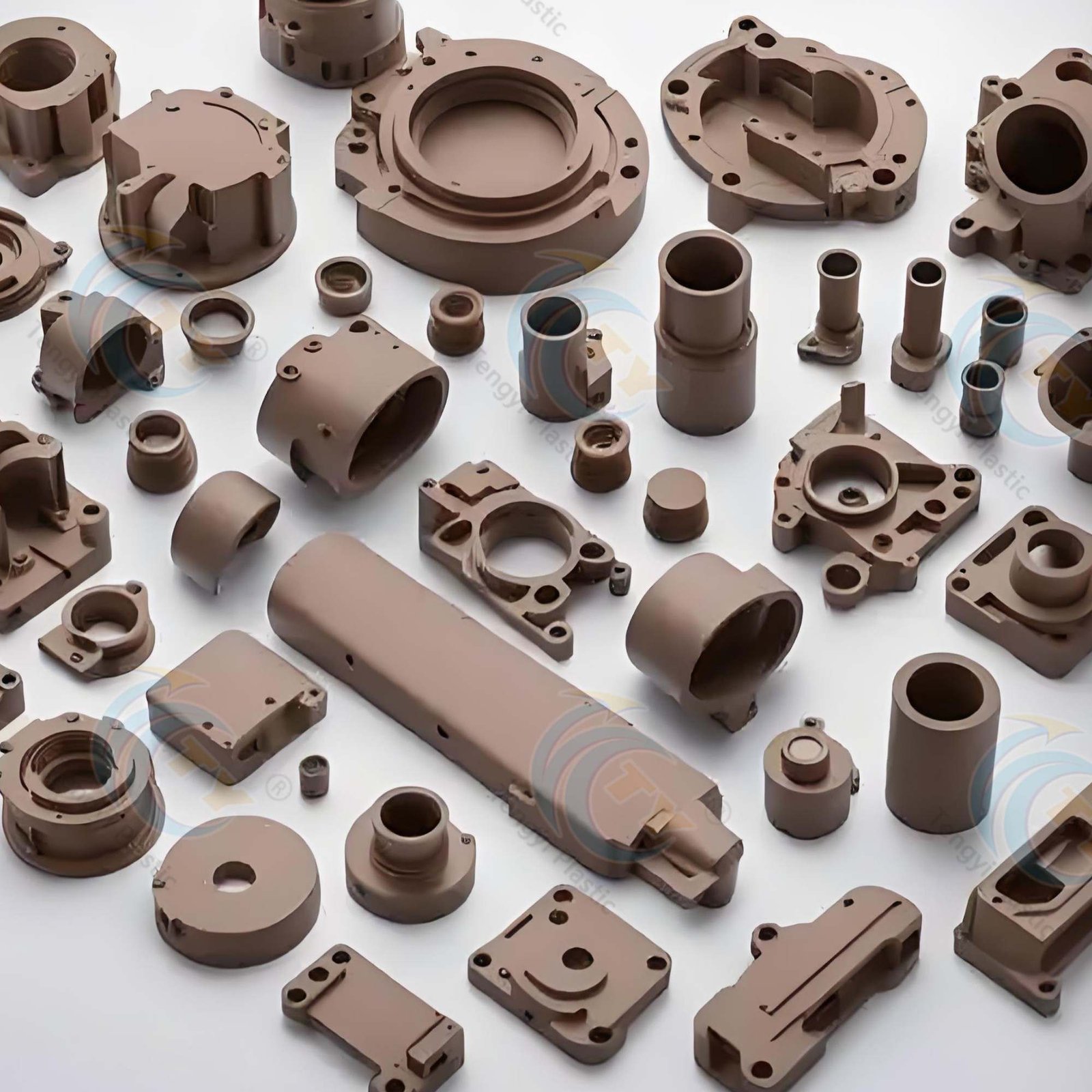

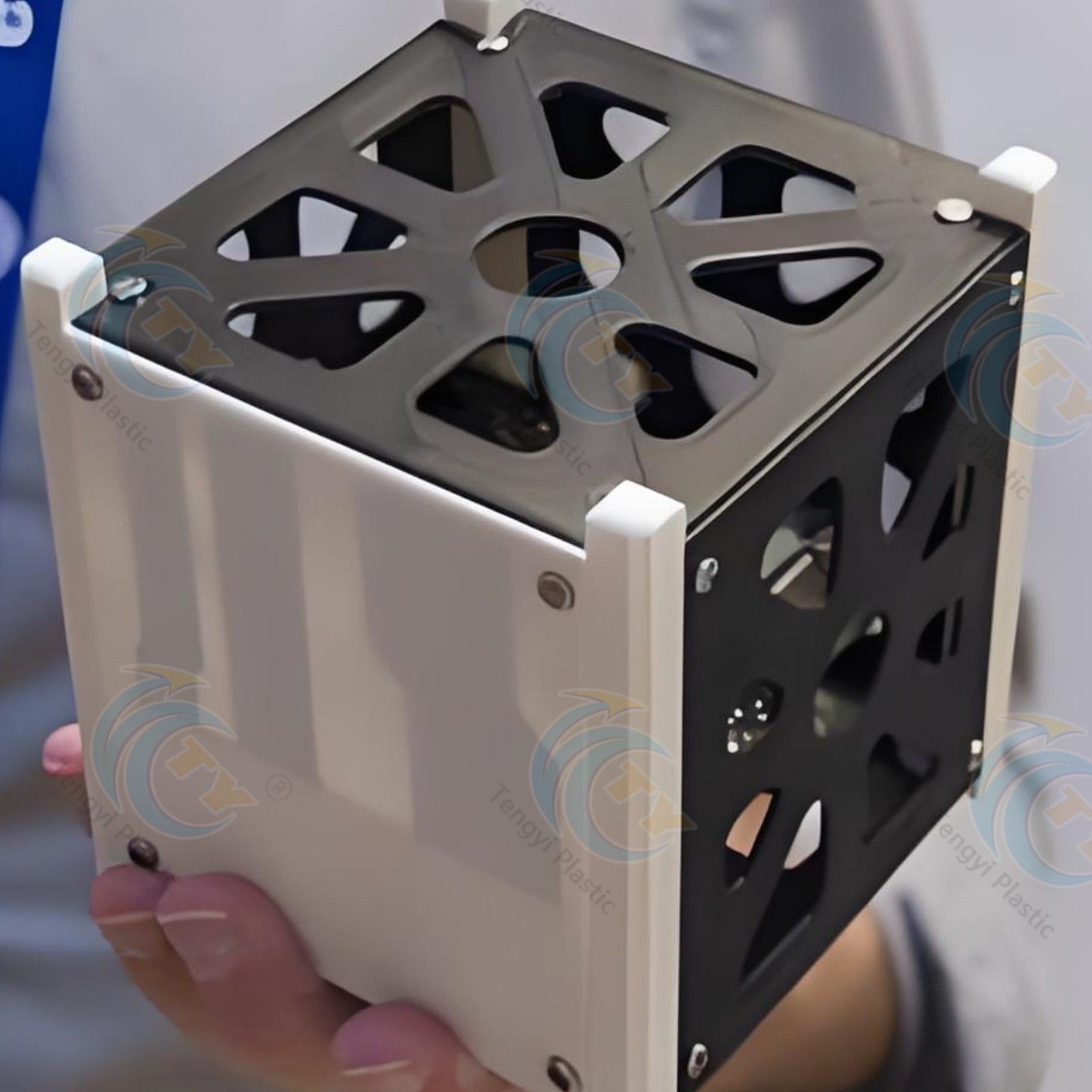

It offers low moisture absorption, excellent wear resistance, and inherent flame retardancy. These properties make PEEK ideal for demanding applications in aerospace (bushings, seals), automotive (gears, bearings), medical (sterilizable components), and industrial sectors (pumps, insulators). Its lightweight yet robust nature outperforms metals in many scenarios, reducing weight and maintenance costs. PEEK’s versatility and durability ensure reliability in extreme environments, making it a top choice for high-performance engineering solutions.

| Size | 600*1200mm |

| Thickness | 1-100mm |

| Colors | Virgin Brown/Black |

| Tỉ trọng | 1.3g/cm3 |

| Extreme Performance | Withstands 260°C long-term, resists chemicals & steam like metals. |

| Light Yet Strong | 50% lighter than aluminum, but similar strength (90+ MPa). |

| Biocompatible & Safe | Sterilizable (autoclavable), UL94 V-0 flame retardant. |

| Key Uses | Aerospace, medical implants, chemical seals. |